What Is the 60/40 Rule for Trailers?

- GGB Products

- Dec 9, 2025

- 4 min read

A Real-World Guide From a Heavy Equipment Trailer Dealer

Most definitions of the 60/40 rule for trailers sound like they were written by someone who’s never hauled anything heavier than lawn chairs. If you’re moving real machines - forklifts, scissor lifts, ATMs, floor scrubbers, vending machines - you don’t load for theory. You load so nothing sways, snaps, drags, or lifts off the road.

Here’s the rule, the real meaning behind it, and how it applies when you’re hauling heavy equipment on drop deck trailers like the ones we sell.

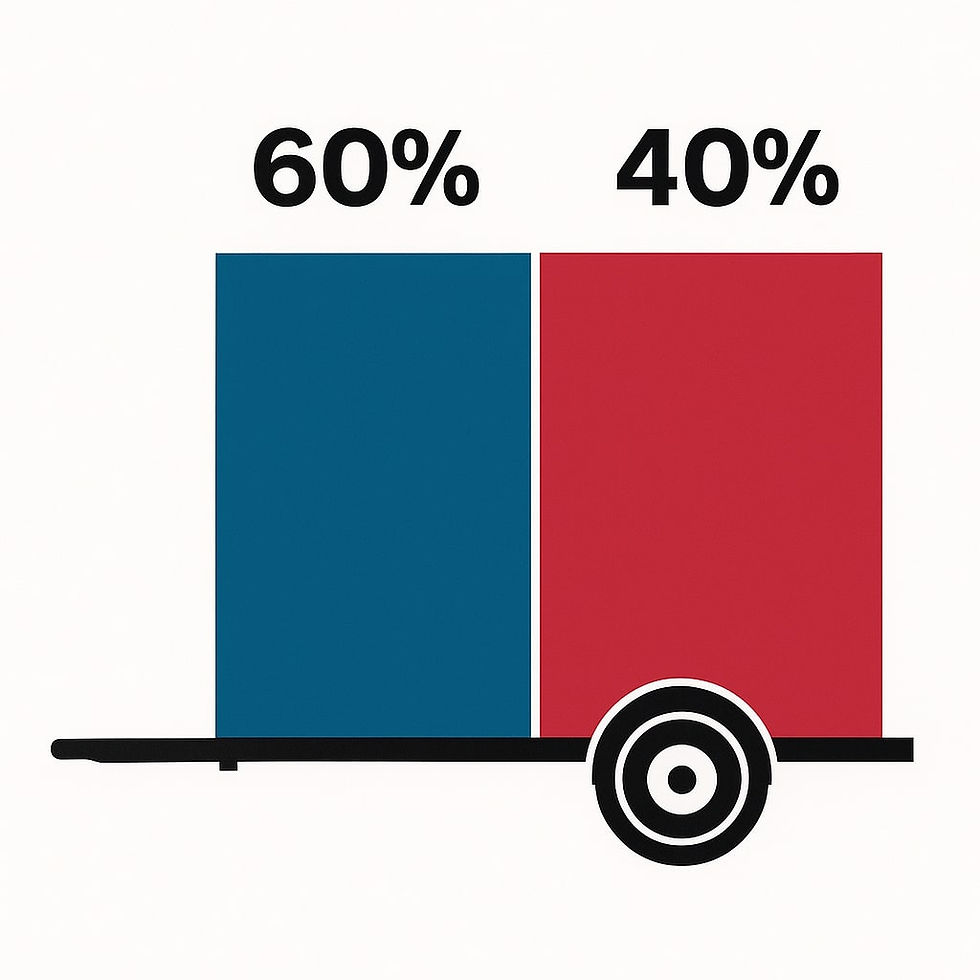

The Simple Definition: 60% Forward, 40% Behind

The 60/40 rule means:

About 60% of the weight should be forward of the axle(s)and 40% behind the axle(s).

This isn’t about “centering the machine in the trailer.” It’s about centering the weight in a way that keeps your trailer straight, stable, and properly weighted on the tongue.

If you ignore it, you risk:

Swaying at speed

Too much pressure on the hitch (bending, squatting, steering problems)

Not enough pressure on the hitch (trailer starts steering you)

Tire blowouts

Axle or suspension issues

You don’t need to be an engineer to get this right. You just need to stop backing machinery in until “the door closes” and calling it good.

The Biggest Mistake We See: “Just Get It Inside the Doors”

We hear this all the time when customers load enclosed drop-deck trailers:

“As long as it’s inside, we’re good.”

No. You’re not good.

People roll the equipment in, shut the doors, and leave the heavy spot wherever it landed. That’s how you end up with:

Too much tongue pressure

Not enough tongue pressure

Weight too far behind the axles

Just because it fits doesn’t mean it’s safe. The job isn’t to get the load in. It’s to get the load balanced.

Does the 60/40 Rule Change for Ground-Level Hydraulic Trailers?

No. The rule doesn’t change.

What does change is your stability and pull quality when the trailer has a better suspension system. The hydraulic drop-deck trailers we sell use an independent torsion-based axle design instead of a typical axle tube. That gives you:

A smoother pull

Less bounce and chatter

Better stability under industrial loads

But here’s the truth:

Great suspension doesn’t save you from bad loading.You still need 60/40 balance.

We don’t pretend that good suspension replaces basic safety. It just makes the pull safer when the load is done right.

How the 60/40 Rule Applies to Uneven Loads (Like Forklifts)

This is where most haulers mess up. Forklifts are heavy in the rear because of the counterweight. That means the weight is not centered where the wheels are.

If you park a forklift in the “middle” of a trailer:

The heavy part may be too far back

You’ll break the 60/40 rule even though it looks centered

Correct way: Make sure the heavy part is over the axles, not visually centered. You may need to load forward more than you expect.

Same logic applies to:

Scissor lifts with rear battery packs

Floor scrubbers with water tanks

ATMs or vending machines when pallet placement shifts weight backward

Don’t eyeball the object. Think about where the weight actually is.

How to Know You’re Loaded Correctly (Without Scales or Math)

You don’t need a calculator. Use these real-world checks:

1. Tongue weight should feel right (not extreme)

General rule: 10–15% of total trailer + cargo weight should be on the tongue.

If your truck sags like it’s dying = too heavy.If your trailer wants to lift the back of your truck = too light.

2. Start driving slow

The first mile tells you everything. If you feel sway, don’t “drive through it.” Stop and fix it.

3. If in doubt, move heavier equipment slightly forward

One shift of as little as 6–12 inches can make a huge difference.

4. Use a hitch with a built-in scale (simple and smart)

These exist. If you haul often, get one.

The Real Problem: People Are in a Hurry

If there’s one myth to kill forever, it’s this:

“If its on the trailer we are good to go”

Wrong. Loading should be right.

We’ve seen more bad loading from rushing than from a lack of knowledge. Take two extra minutes. Check your tongue weight. Pay attention to where the heavy end of the machine is sitting.

It’s not complicated, unless you make it complicated by being careless.

Safe Loading in 3 Simple Steps

You don’t need a seminar. Use this:

Step 1: Know where the heavy end of the machine is

(Back of forklift, battery side of scissor lift, water tank side of scrubber, etc.)

Step 2: Place that heavy end over the axles

Err slightly toward the front — never the rear.

Step 3: Check your tongue weight, then drive slow at first

Correct if needed. Don’t be stubborn.

Want Expert Help Choosing the Right Trailer for Your Equipment?

At Drop Deck Direct, we don’t just sell trailers. We match the right model to what you load, how you load, and how often.

If you want help choosing a trailer — or want guidance on loading equipment safely — reach out. We’ll talk through:

Your machine weights

Your loading habits

Your hitch setup

Whether you need flatbed or enclosed

Request a quote + free loading guidance: We’ll help you get it right the first time.

Comments