Understanding Drop Deck Trailer Weight Distribution for Safe and Legal Hauling

- GGB Products

- Sep 4, 2025

- 2 min read

Updated: Dec 9, 2025

Every year, thousands of loads are cited for improper weight distribution—and many of those citations could have been avoided with the right loading strategy. Beyond fines, poor trailer loading can damage equipment, increase accident risks, and shorten the life of your trailer. At Drop Deck Direct, we know that safe hauling starts with one critical principle: Drop Deck Trailer Weight Distribution.

Why Weight Distribution Matters

Weight distribution isn’t just a box you check for compliance. It’s the foundation of how your trailer tows, brakes, and handles on the road. When weight is uneven, the trailer sways, axles wear unevenly, and braking distances increase dramatically. Worse, overloading the wrong axle can push you past legal limits—even if your trailer technically has capacity.

That’s why understanding the proper balance point isn’t optional—it’s essential.

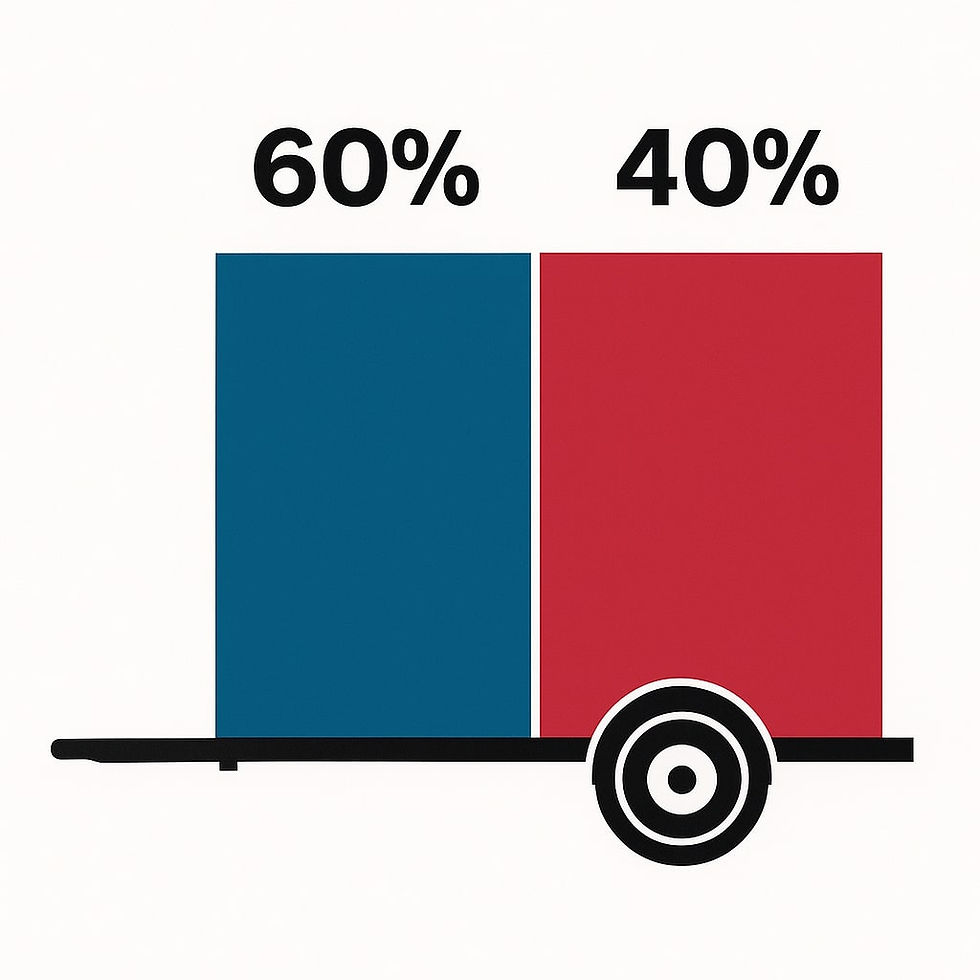

The Golden Rule: 60/40 Trailer Loading

A proven guideline for most equipment trailers is the 60/40 trailer loading principle. This means:

60% of the total weight should sit forward of the axle centerline.

40% of the total weight should sit behind it.

This simple ratio keeps your trailer tongue weight within the optimal range—heavy enough to avoid sway, but not so heavy that it overloads your tow vehicle. Think of it as the “sweet spot” that balances stability with safety.

Practical Steps for Proper Drop Deck Trailer Weight Distribution

Step 1: Know Your Trailer’s Capacity

Before loading, confirm your trailer’s Gross Vehicle Weight Rating (GVWR). A Drop Deck Trailer Weight Distribution plan means nothing if you exceed the GVWR. Always include the weight of the trailer itself in your calculation.

Step 2: Load the Heaviest Equipment First

Forklifts, scissor lifts, or mini excavators should be placed forward of the axles—never at the rear. This secures tongue weight and prevents the dangerous “tail wagging the dog” effect on highways.

Step 3: Check Axle Loads

Each axle has a rating. Distribute equipment so no single axle is overloaded. Overstressing one axle, even if under GVWR, can lead to long term issues.

Step 4: Secure the Load

Straps and chains don’t just prevent shifting—they help maintain the carefully planned weight distribution. Always use rated tie-down points and equipment-grade hardware.

Signs of Improper Weight Distribution

Even if you follow the 60/40 rule, you should know the red flags of bad loading:

Excessive trailer sway at highway speeds

Rear of the tow vehicle sagging noticeably

Uneven tire wear patterns

Axle or tongue overheating after long hauls

If you see these, stop and re-balance before continuing.

The Legal Side of Weight Distribution

DOT regulations are strict about axle weight limits. Even when under your total GVWR, exceeding axle ratings can earn you fines or force roadside unloading. Proper Drop Deck Trailer Weight Distribution is the best defense against unexpected legal headaches.

Final Thoughts

Loading a trailer isn’t complicated—but it’s also not something you can wing. By sticking to the 60/40 trailer loading principle, double-checking axle weights, and securing every piece of equipment, you’ll protect your investment, stay legal, and keep every haul safe.

At Drop Deck Direct, we believe a well-loaded trailer isn’t just efficient—it’s peace of mind. Safe, smooth, and built to go the distance.

Comments